LPG Storage Automation

The key to fully functional automation is the compliance in between the equipments. PLC Control Panel, Mass Flow Meters, Level Measurement Devices and Detectors we offer are in absolute harmony with each other and our storage units.

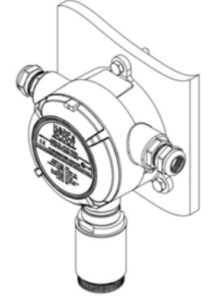

- Gas Detectors are compatible with appreciated MARU PLC Control Panels.

- Ensures safety of your LPG tanks, stations and plants.

- In case of emergency, shuts off the whole system accompanied by visual and audial alarms.

| Working Voltage | 24 ±25% VDC |

| Analog Out | 4 ~ 20 mA |

| Digital Out | 2 Relay Outputs, Both NC and NO |

| Measurement Range | 0-100 %LEL |

| Resolution | 1 %LEL |

| Response Time (T90) | <10 second |

| Enclosure Material | Aluminium |

| Sensor Type | Catalytic |

| Environmental Conditions | Temperature -20 ºC ~ +60 ºC, Pressure: 86-106 kPa, Humidity: ≤90 %RH |

| IP Protection Level | IP65 |

| Atex Classification | II 2 G Ex d IIC Gb T6 |

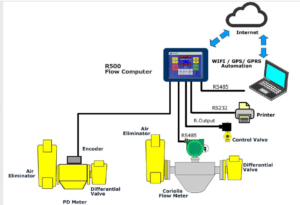

- Especially developed for our LPG storage tanks, Maru PLC Control Panel enables you to save money by buying only the module needed.

- Customise without any extra charges when you change accessories such as probes or level gauges.

- Provides perfect software-hardware integration

| Graphic Display | 320x240 Color LCD (3,2") |

| Power Input | 24VDC instrinsically safe barrier |

| Power Consumption | <1W |

| Measurement Principle | Coriolis or PD Meter (Optional) |

| Protection Class | IP66 |

| Atex Marking | Ex II2G Ex db IIB T4 Gb IP66 |

| Operating Temperature | -25 ºC to 55 ºC |

| Measurement Range | 0 … 750 kg/min |

| Communication with Measurement Devices | Modbus (E+H, Micromotion) Optional Pulse Counting |

| Measurement Accuracy | ±0,2% - 0,5% (Based on Measurement Unit) |

| Inputs | Communication Ports 0 … 10V or 4-20 mA Sensor 2 Channel Pulse Input |

| Outputs | 24V Relays 24V Power |

| Communication Options | RS485, RS232, WIFI, RFID, Optional GPS, GPRS and Bluetooth |

| Memory | Micro SD Card 8GB or more RAM: 256 KB FRAM: 8KB |

| Language Support | English (Optional: Italian, Russian, Turkish, Serbian and Spanish |

We offer various solutions to our customers for LPG measurement of tank levels;

- Magnetic level gauges

- LPG Probes

- LPG Radars (High frequency microwave pulses)

MAGNETIC LEVEL GAUGE

- An economical solution for level measurement.

- Can be used in vertical or horizontal position.

- Sends data to panel via transmitter.

LPG PROBES

- A more accurate way to measure tank levels.

- Unlike the magnetic level gauge, this product has no elbows.

- The magnetic ring moving vertically along the probe generates a smooth and accurate measurement without problems, for years.

- High quality and durable product made in Italy. * Transmits data to PLC Control Panel easily.

LPG RADARS

- This is the most accurate solution for measuring tank levels.

- Has no moving parts, thus never has mechanical problems caused by dirt or corrosion.

- Uses high frequency microwave pulses to measure tank level very precisely.

- Can transmit data via bluetooth or cable.